diary of a chocolate Maker: Conche repair

If you've taken a factory tour, you know that turning cacao into chocolate takes a lot of steps. One big stop along the way is refining, which we do in part in a horizontal conche.

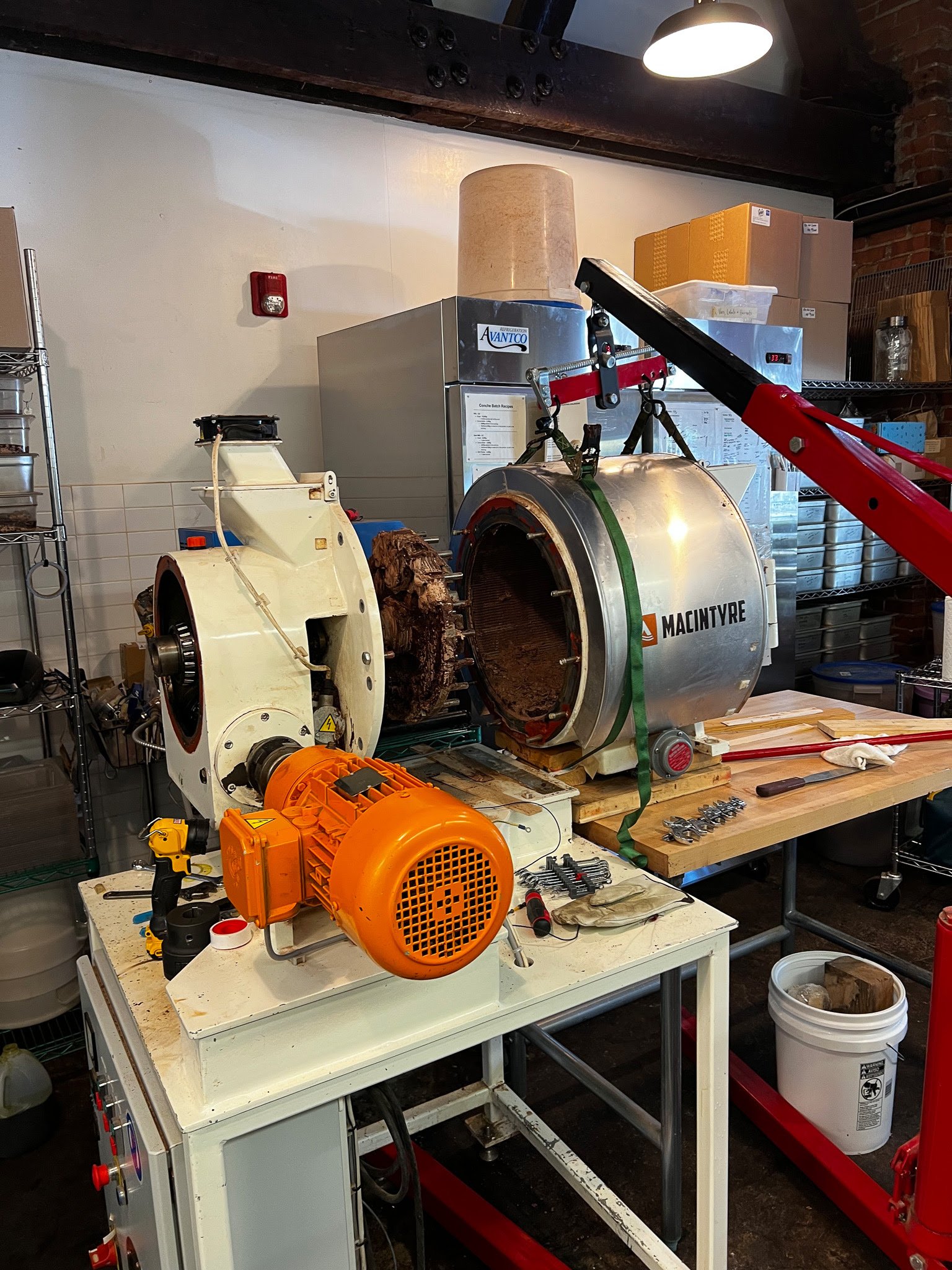

A few months ago, the time came to take apart the conche to perform yearly maintenance. On a daily basis, we inspect the conche tension, gasket and seal function, and temperature control via the glycol coolant system. Mordecai was alerted by a subtle whine & a change in tension of the machine, and a few of the seals were less functional. Time to go in!

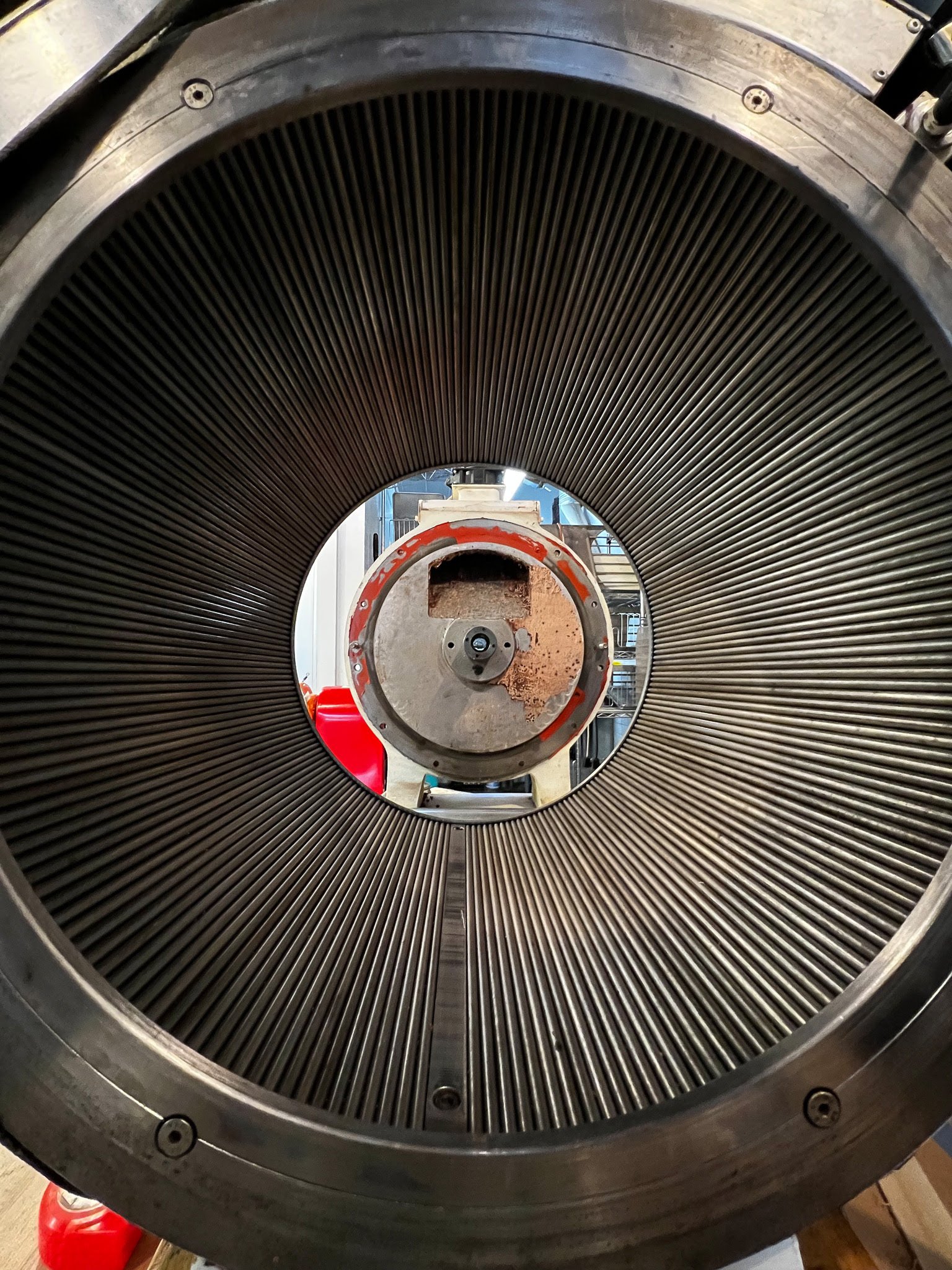

The interior of the conche has over 200 blades in the liner (also called "drum liner bars") and another 24 "beater bars" (yup, more blades). These all dull over time from shearing cocoa nibs and sugar together—creating the decadent texture and sweetness of Videri chocolate. All of our 70% dark chocolate passes through this machine for 16 hours of refining and mixing. Its easy to say that this conche is essential to our whole operation.

Mordecai opens the horozontal conche — notice the blades covered in chocolate! What a delicious mess.

First, Mordecai (above), took the entire machine apart with the assistance of an engine lift. Then he replaced each of those blades (yes all 200+) on the inside of the conch. This meticulous process took an entire week to complete.

Conche Interior: 200 Refining Blades

Notice the size, number, and placement of each drum liner bar & beater bar. This cylinder rotates in a clockwise fashion, and each bar comes together to refine the added chocolate & sugar. This is essential to the texture and flavor of Videri Chocolate!

How does one learn to do conche repair? The first time we opened the conche in 2020, COVID posed an interesting challenge. There were no in-person options for tech support, so instead, Mordecai spent hours on a Facetime call with a technician in Scotland, learning and documenting his way through the process. There’s nothing quite like a trial by fire of dismantling, labeling, referencing manuals, and taking video and photography of how the puzzle fits together. Thankfully, Mordecai was able to lean on his practice with the conche’s little brother, who we use for our 55% Dark Milk chocolate, due to their similar concept, design, and structure.

After a week of monumental effort, and all of us cheering him along, Mordecai tightened the last bolt. We took a deep, relieving breath as the conch turned on and the well-tuned hum filled the factory floor— it was fixed!

Take a look below to see Mordecai in action and then please join us in thanking him for taking on such a intense and essential project! Our small business works because of the truly awesome people that work in it.